|

|

|

|

| |

|

|

|

| |

|

Vidur

|

|

|

|

|

|

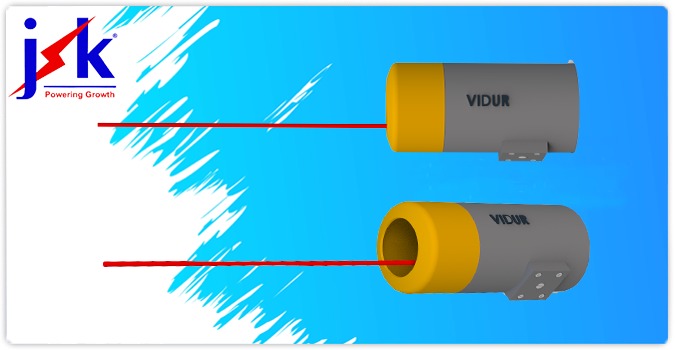

VIDUR (Vibration Intelligence Data Unravelling Remotely):- VIDUR is a breakthrough in technology that can monitor the health and quality of rail while the Train is moving at high speed.

|

a. Online Track Monitoring: - (SPURT) VIDUR is installed onboard in front of the engine.

- Crack, Slag, Porosity,

- Chipping off of Railhead / Thickness or surface of rail that reduces even less than 5 mm.

- Fish plate removal, loosen nut bolts.

- Metal shrinkage during winters and expansion during hot weather results in Buckling, Sun kinks or rail slagging of long welded rail (LWR), and other environmental impacts like snow and ice that could make slippery rail resulting in train derailment and mishaps.

- The blockades on the Track include boulders, trees, animal seating or crossing, and vehicles that are jammed on the Track.

- Soil erosion or floods cause the elimination of the complete ballast of the Track, and rail stays suspended.

- Soil erosion or floods cause the elimination of the complete ballast of the Track, and rail stays suspended.

- VIDUR will display signal aspects and other monitoring parameters in the loco pilot cabin

|

|

b. Train Collision Avoidance System (TCAS):

d. Train Collusion Avoidance system (TCAS)

VIDUR prevents head-on collisions that could result in human loss / collateral damage. Thereby saving in colossal capital cost.

-

VIDUR prevents head-on collisions that could result in human loss / collateral damage. Thereby saving in colossal capital cost.

- If the distance between 2 trains is nearing to be less than 5 KMS, then alerts and alarms will be signaled as well as auto pilot in slowing or stopping the trailing Train can be triggered or stop signal can be activated.

- The distance between 2 trains can be minimum of 1 Km to 35 km. Hence VIDUR can act as full proof TCAS.

- VIDUR will monitor the speed of Train & will be able to supervise train movement and shunting limits.

|

|

c. Bridge Monitoring:- VIDUR compliments VEDA. Once VEDA alerts abnormality of the bridge, the handheld device of VIDUR will be used to:-

-

Detecting the existence of Damage to the infrastructure

- Locating the damage/porosity

- Identifying the types of Damage

- Quantifying the severity of the Damage

- Quantifying the severity of the Damage

- VIDUR can seamlessly do Vibration monitoring of Steel and Civil Structure

|

|

d. Condition and Vibration Monitoring: - VIDUR is the worlds one of its kind non-contacting probe technology in monitoring any Vibration of Machines. VIDUR has the ability to monitor all important moving and static components of any machine.

Predictive and preventive maintenance of rail is integrated to avoid delay & hardship. The restoration time is fast as the whole system is built on the Internet of Things. The disaster management team or nearby Railway Station Engineer will be immediately summoned about the type of obstruction or Damage. Corrective measures can be taken directly

The lethal combination of VEDA & VIDUR enables seamless commuting of trains.

|

|

INTEROPERABILITY, COMMUNICATION COMMAND AND CONTROL AND BIG DATA

The photonic technologies and systems will transform the Train as a Sensor. Every Train will communicate with other trains, stations, linemen, etc. with relevant information illustrated (and exhaustive in its coverage as under: The communication between 2 or more trains can take place at min distance of 5 km and max upto 50 km. Following are the information and alert that can be transmitted.

VIDUR is the worlds one of its kind non-contacting probe technology in monitoring any Vibration of Machines. VIDUR has the ability to monitor all important moving and static components of any machine.

- Blockade on Track

- Overflooding on Track

- Damage on Track.

- Repairs work

- Environmental conditions like density of fog, rainfall, visibility etc

- Bridges / Tunnel crossing.

- Red Signal overrun.

- Crossing through red zones / Naxal areas.

- Railway crossings

- Accident, Fire, or other hazards on the Train.

- Untimely / urgent stoppage of Train on non-earmarked location or Station that is not predetermined.

|

|

With the Array of Things enabled platform, Photonic sensing is operated remotely. Information, alerts, alarms, etc. can be provided on any communication protocols. Post repairs, analysis of specific deflection or alleviated damages are also monitored. Historical patterns are stored to give the correct prediction, prevention and protection of assets. Trains as a Sensor will communicate data that can be immensely useful during Disaster management.

|

|

Photonic Systems, Big Data Analytical platform integrated with Command and Control, will perform in tandem for predicting, Preventive. Prescriptive and Geospatial analytics.

|

|

THIS REAL-TIME ANALYSIS WILL PROTECT, PREVENT AND PRESERVE HUMAN AND MACHINE LIFE.

|

| |

|

| |

|

|

|

|

|

|

|